Overview

Millimetre scale five-hole probes are required to resolve and accurately measure small flow features. However, careful consideration of the internal geometry of the probe is needed to minimise the settling time required.

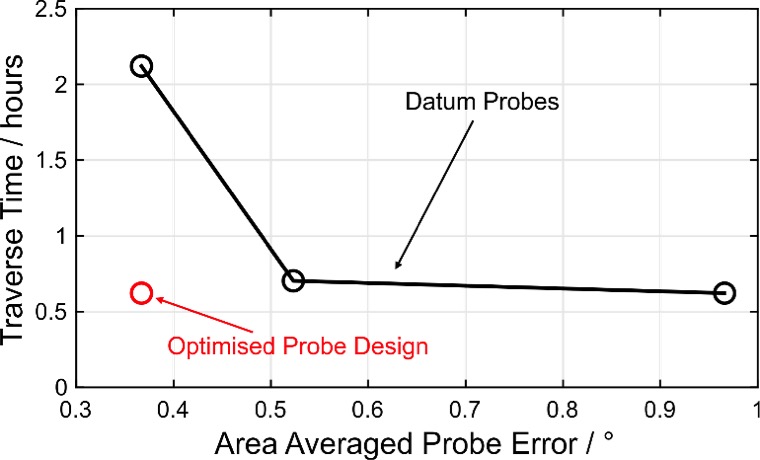

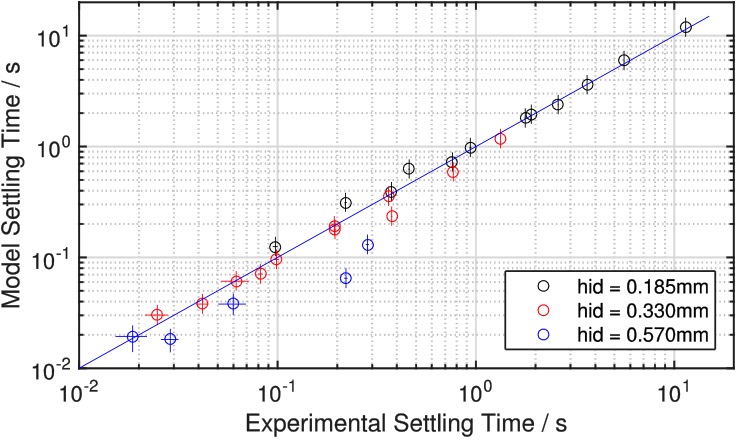

This work investigates how the external geometry of a five-hole probe affects its accuracy and how internal geometry affects its settling time. An analytical model, which predicts settling time, is used to design an accurate, fast-settling, millimetre-scale probe. The study has been split into three components:First, a series of area traverses were performed with three five-hole probes which range in head diameter from 0.99 to 2.67 mm. Figure 1 shows that the smallest probe gives the greatest accuracy when traversing the shear layers in blade wakes. However, it takes 3.4 times longer to complete this traverse than compared to the largest probe. This is because traverses with small probes require more time to allow the pressure readings to settle between each traverse position. First, a series of area traverses were performed with three five-hole probes which range in head diameter from 0.99 to 2.67 mm. Figure 1 shows that the smallest probe gives the greatest accuracy when traversing the shear layers in blade wakes. However, it takes 3.4 times longer to complete this traverse than compared to the largest probe. This is because traverses with small probes require more time to allow the pressure readings to settle between each traverse position.Second, an analytical model was developed which predicts settling time based Second, an analytical model was developed which predicts settling time based upon the internal geometry of the probe. The approach adopted is capable of modeling any number of connected tubes with different lengths and diameters. It is validated against experimentalMeasurements (Fig. 2) and is shown to give good agreement. This model can be used to ensure that probes are designed with acceptable settling times. Finally, the analytical model is used to design an optimised five hole probe (red circle in Fig. 1). Use of the model highlights two important results which are required to reduce settling time: First, the length of the smallest diameter tubes, i.e. the ones in the probe head, should be minimised. Second, the volume of tubing downstream of the head should be minimised. Applying these principles to a new probe design cuts the total traverse time by 71%, while maintaining the highest value of accuracy.

Figure 1 Trade between total traverse time and probe error for datum probes and optimised design with low traverse time and error.

Figure 2 Comparison of measured and predicted settling times for varying hypodermic tube internal diameter, length and connecting tube length

Key stats

Time to perform an area traverse with 0.99mm head five hole probe reduced from 126 minutes to 37 minutes, a reduction of 71%Associated Team