Extending the operating range of compressors offers the potential for increased pressure rise and improved efficiency.

At low flow rates, rotating stall and surge are the fundamental limits of a compressor's operating range. Rotating stall, which can lead to surge, is analogous to wing stall in external flow: as the flow rate is reduced the compressor delivers a higher and higher pressure rise until, suddenly, the flow field is partly or entirely disrupted - and with it the pressure rise. The Whittle Laboratory has a long history in stall and surge research. Dr Ivor Day has lead several experimental campaigns to uncover the behaviour of compressors both within and immediately prior to stall. Two routes to rotating stall emerged: "modal" and "spike" stall inception. In the former, small circumferential perturbations to the flow (on a wavelength of the order of the machine circumference) grow exponentially in amplitude over 10's of revolutions. In the latter, a large amplitude but short length scale (blade pitch) disturbances, observed as a "spike" in pressure transducer data, leads to rotating stall within only a few revolutions. Modal stall has been amenable to reduced order modelling and Drs Hynes and Longley have among the leading practitioners in this field.

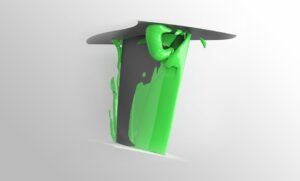

As the capabilities of computer hardware increased, in particular the acceleration offered by running flow solvers on Graphics Processing Units, it became possible to capture spike-type stall inception computationally. In a joint project with Professors Greitzer and Spakovszky at MIT, Dr Graham Pullan used CFD to uncover the origins and structure of the spike. With experimental corroboration from Dr Anna Young, the team showed that spikes are, in fact, vortex tubes formed when vorticity is shed from the leading edge of the compressor blade at high incidence.

Current projects address the effects tip clearance, and the multi-stage environment, on rotating stall.

The stalling of an axial compressor

When the flow through an axial compressor is restricted, the discharge pressure will rise. With further flow restriction, the exit pressure will increase to a maximum and then the compressor will stall. Stalling produces a very rapid loss of pressure rise which will not be restored until the exit restriction is removed and the flow rate is greatly increased. In the video clip, the exit area of the compressor is mechanically controlled by the rotation of the throttle wheel.Associated Team